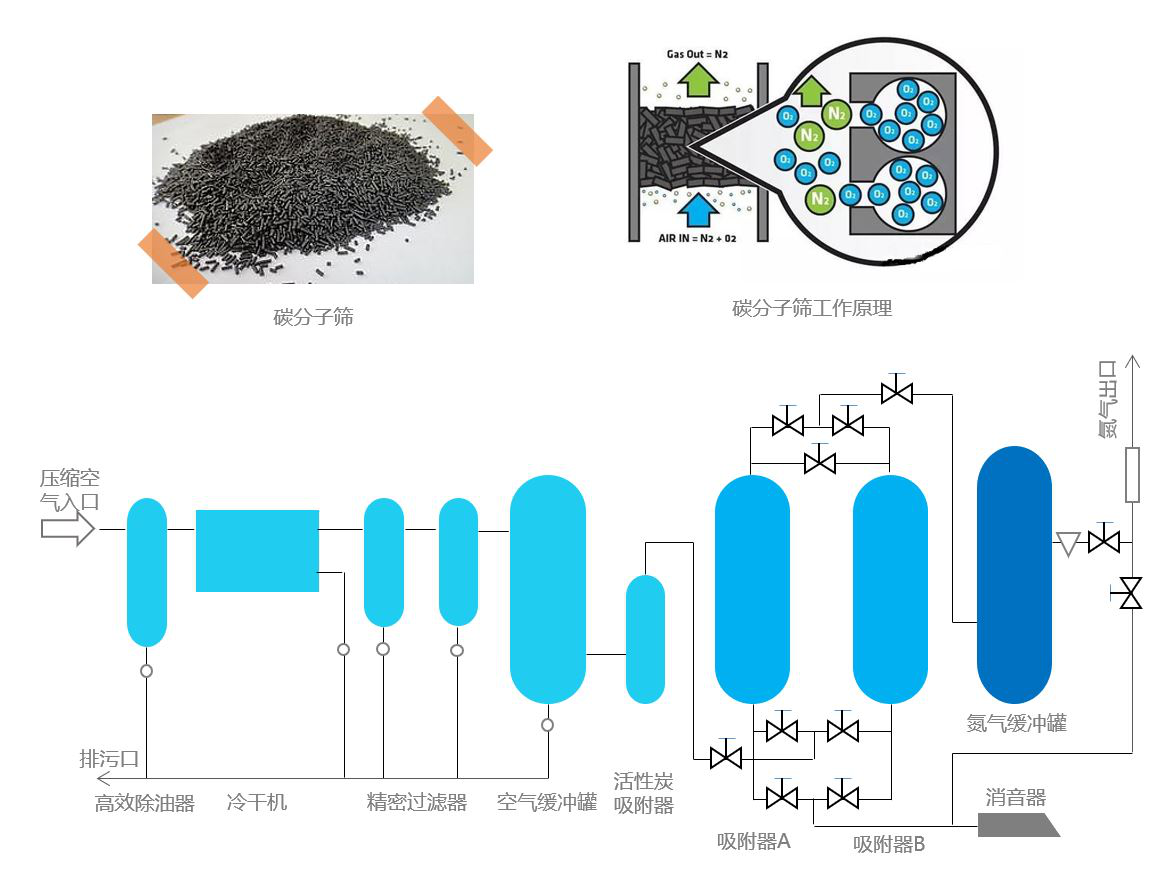

PSA nitrogen generator

Principle of nitrogen production

The normal air composition is about 78% N 2,21% o 2,0.939% He, Ne, AR, KR, Xe, Rn and 0.031% co 2 by volume fraction, there are other gases and impurities accounting for about 0.03% , such as ozone o 3, Nitric Oxide, Nitrogen Dioxide, water vapor (H2o) and so on.

The pore size distribution of carbon molecular sieves makes it possible to realize the kinetic separation of o 2 and N 2. This pore size distribution allows different gases to diffuse at different rates into the micropores of the zeolite without repelling any of the gases in the mixture. The separation of o 2 and n 2 by Carbon Molecular Sieves is based on the slight difference in the kinetic diameters of the two gases. The kinetic diameters of o 2 molecules are smaller, so they have a faster diffusion rate in the micropores of carbon molecular sieves, the kinetic diameter of N2 molecule is larger, so the diffusion rate is slower. The diffusion of water and CO2 in Compressed air is similar to that of oxygen, while Argon diffuses more slowly. Finally enriched from the adsorption tower is the mixture of N2 and AR.

Pressure Swing adsorption (PSA) is a selective adsorption of carbon molecular sieve, the use of pressure adsorption, decompression and desorption cycle, so that the Compressed air alternately into the adsorption tower (can also be completed by a single tower) to achieve air separation, thus continuous production of high purity product nitrogen.