Nitrogen purification plant

How it works

In some special industries or processes with high requirements for atmosphere, nitrogen purity needs to be raised to 99.9995% or higher. The nitrogen purification process of our company is about to produce water, carbon dioxide, carbon monoxide and so on by adding hydrogen or carbon into the ordinary nitrogen (generally 99-99.9% purity) and reacting with oxygen in the nitrogen under the action of catalyst, then the secondary reaction products are adsorbed by the later molecular sieve to obtain high purity nitrogen.

Hydropurification

After a mixture of nitrogen and a small amount of hydrogen produced by PSA or Membrane System, the residual oxygen reacts with Hydrogen to Form Water Vapor in a reactor filled with palladium catalyst, and then most of the water vapor condenses down through a subsequent cooler, and through the efficient water separator to remove condensate, adsorption dryer can make the product gas dew point up to-70 °c below. The product gas purity is continuously monitored on-line by the analyzer.

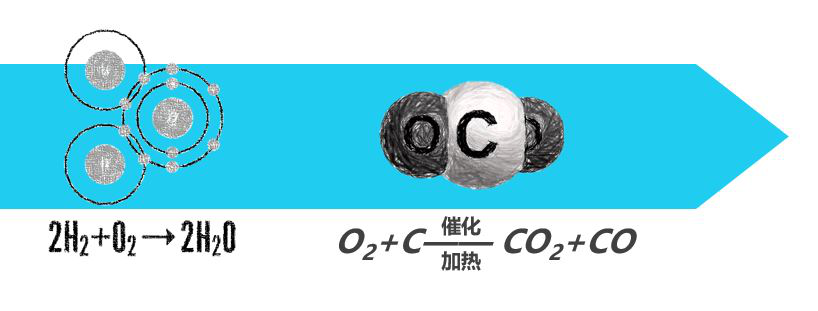

The chemical equation is 2H2 + o22h2o + heat

In order to ensure the complete removal of oxygen, the actual ratio of H2 to O2 is slightly higher than the theoretical value. If the oxygen content in the imported raw material nitrogen is higher than L. 5vol% , a multi-stage treatment system can be adopted. The purity of nitrogen can reach 99.9995% after refining.

Hydrogen purification is especially suitable for the nitrogen need a bit of hydrogen heat treatment and other industries.

Carbon purification

For processes where hydrogen is sensitive or where hydrogen sources are difficult, carbon-supported deoxidization may be used. High purity nitrogen of 99.999% can be obtained by the reaction of nitrogen with excess carbon fine to produce C02 at high temperature and then through the adsorption tower of decarburized oxides.

Chemical Equation: C + o 2 CO2 + heat

The carbon-carried purification N2 device consists of a heater, a reaction tower, a water cooler, a CO2 removal and adsorption tower, an oxygen analyzer, a flowmeter, and a product nitrogen buffer tank.

In order to reduce the replacement frequency of carbon fiber, improve the utilization ratio of equipment and reduce the tedious work of replacing carbon fiber, the purity of crude nitrogen is generally recommended at 99.9% , under this purity condition, the balance of power consumption of air compressor and carbon fiber consumption can be taken into account.

Technical parameter

Flow: 3-5500nm 3 / H

PRESSURE: 0.3-0.5 MPA

dew point: ≤-73 °C purity: 99.999%-99.9998%

oxygen content: ≤3 PPM

residual hydrogen content: ≤1000 PPM (hydrogenated)

carbon dioxide content: ≤10 PPM (carbonated)

)