Methanol cracking hydrogen production system

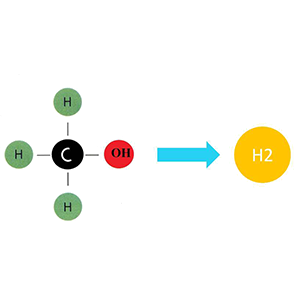

Principle of methanol cracking process

The superheated steam mixed with methanol and water in a certain proportion takes place the catalytic cracking reaction and carbon monoxide shift reaction at the same time through the action of catalyst at a certain temperature and pressure, the result is a mixture of hydrogen and carbon dioxide. The methanol-water cracking reaction is a multi-component, multi-reaction gas-solid catalytic complex reaction system.

The main reactions were:

CH3OH Û CO + 2H2-Q1

CO+H2O Û CO2 + H2+ Q2

The total reaction was:

CH3OH+H2O Û CO2 + 3H2- Q

After heat transfer, condensation and water washing, the converted gas with hydrogen content ~ 74% H 2, CO2 content ~ 24.5% and CO content ~ 0.5% was obtained. The one-way conversion rate of methanol is over 93% , the product hydrogen with high purity is obtained by pressure swing adsorption, and the unreacted raw materials (methanol, desalted water) are recycled. The main gas components of converted gas are h 2≈74.5% , CO 2≈24.5% , CO ≈0.5% , saturated water and trace, trace CH4 and other products.

Flow: within 10000nm 3 / H

hydrogen purity: 99.9-99.9997%

methanol consumption: 0.57-0.65 kgch3oh / Nm3H2

power consumption: ≤0.1 kw / Nm3H2